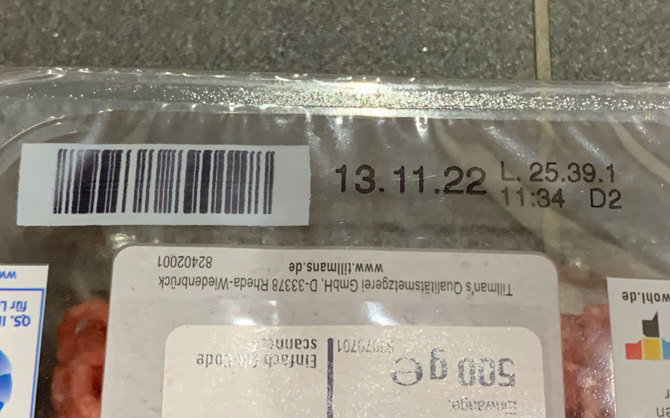

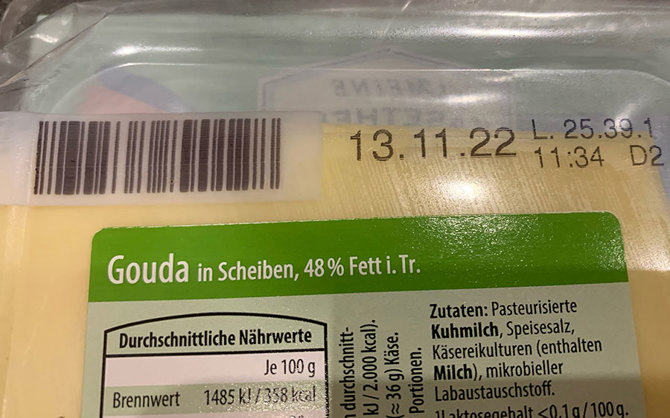

Direct printing instead of label

Important information must be clearly readable. On smooth surfaces as well as transparent and dark substrates, this is already a challenge. Labels were therefore always well suited for packaging made of smooth plastics, or foil – especially for transparent or dark materials. Likewise, important data on products made of metal, such as drywall profiles, preferred to be printed on a label that was then applied.

Especially in times of massive shortages of primary materials, sustainability, and resource conservation, switching to “wet-on-wet” direct printing is a real alternative to self-adhesive labels.

What is wet-on-wet printing?

Novel printing process in one work step

In wet-on-wet printing, two or more colors are printed in immediate succession – without any drying time in between. This means that color mirrors, codes and plain text are printed in a single step. The color mirror is applied first, and important information is printed on it in the same step – either with black or colored ink, but in any case in high resolution. The color mirror and marking then dry together in a very short time.

This innovative wet-on-wet printing process neither limits production output nor does the readability of the printed image suffer. Quite the opposite. The previous drying time is eliminated, printing takes place in a single step, and contrast is optimal. Thus, the new printing process enables a high first-pass reading rate for 1 and 2D codes, text lines and logos with variable information such as date, time, counter, shift code and database content.

Which coding and marking system is used to implement this printing technology?

High Resolution Inkjet Printer and Inline Print Control

Innovative wet-on-wet printing is implemented with the REA JET HR Inkjet Printer. With HP cartridge technology and a resolution of up to 600 dpi, it prints codes, texts and logos in one work step – in direct succession, without interruption or drying time. This is because the use of newly developed inks means that smooth or transparent surfaces, such as foils, plastic or metal, can be marked cleanly, in an environmentally friendly manner and without solvents. The result is high-contrast, clearly readable, captive, and all this at high printing speeds.

This produces print images up to 12.7 millimeters high per print head, and several print heads can be cascaded for images up to 50.8 millimeters high.

Hot swap function

The “hot swap function” enables cartridges to be changed during operation. As each cartridge is supplied with a new print head, the system is maintenance-free, ensuring uninterrupted product marking. Heatable print heads ensure unchanged high print quality even in cold production environments.

Inline printing process

The wet-on-wet printing process can be ideally combined with the innovative REA Inline OCR solution: Mounted above the conveyor belt and equipped with powerful optical text recognition (OCR) software, a camera system reads marking and codes on passing product packages and checks their accuracy. Capture and complete evaluation are completed in the shortest possible time, at just 70 milliseconds per print element. Completely integrated into the production and packaging process, it ensures that only fully and correctly marked goods are delivered.

What are the advantages of wet-on-wet printing?

Clearly readable, high contrast and abrasion resistant

- No bottlenecks in material supply and thus no production downtime, ability to deliver is maintained

- No expensive downtimes due to makeready for product changes, for label roll changes or for changing carton layouts

- Economical ink consumption

- Higher printing speed

- Captive, and therefore no peeling of the print or poor adhesion

- Disposal of printed packaging of the correct type promotes the recycling rate

- On-the-fly cartridge change

- Reduced waste due to elimination of label backing paper

- Adhesion even to oily substrates

- Low maintenance requirements

- Lower printing costs per print