Why verify label layouts and contents?

Label layouts and contents on packaging and products must not only be 100% present, but also correct and legible. Because clearly visible, legible and correct data is essential for manufacturers and retailers to comply with legal requirements, carry out controls during import, prevent contractual penalties or avoid complaints and expensive recalls. Quality control and avoidance of errors during labeling and marking are the decisive keywords here!

How can errors be avoided during labeling and marking?

Visual inspection and dual control principle

Visual inspection during quality control can reduce, but not eliminate, confusion of print layouts or labels, number errors, incorrect language selection or simply careless mistakes. Furthermore, visual inspection requires a considerable amount of time and personnel and still contains a residual risk despite the dual control principle.

It is also tricky if the product has been correctly marked, but in the wrong language. Not every employee can speak several languages fluently or recognize immediately and without doubt which language it is. The fact that a product has been labeled in the wrong language is usually only noticed after numerous batches have been produced.

Inline controls would be a solution, but simply not practical. The associated setup effort for the variety of different packaging such as stretch foil, cardboard boxes, tubular bags, etc., would cause the effort and costs to explode.

Innovative solution

Verification before production starts

An innovative solution for verifying codes and layouts is digital image processing combined with artificial intelligence, which opens up new efficient and reliable ways of quality control. Label data can thus be verified quickly and reliably for presence, correctness, readability and completeness. It is irrelevant whether the data is static or variable.

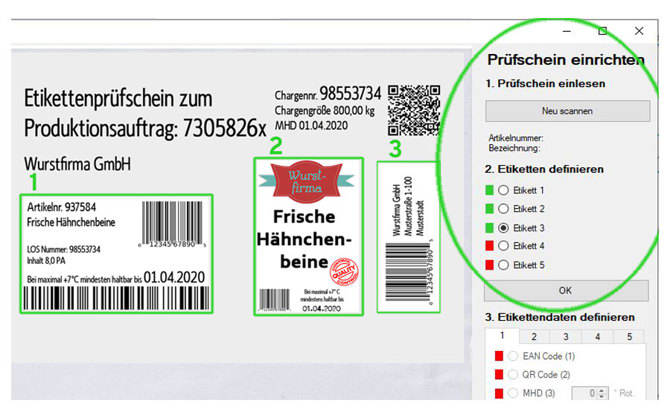

The labels are verified before production begins. For this purpose, the software is taught a product range of any size in a previous step. After scanning these sample sheets, first the individual labels are defined in a clear and well-structured mask, followed by the respective data – usually an EAN code, the label number, the best-before date, the LOT number and a QR code.

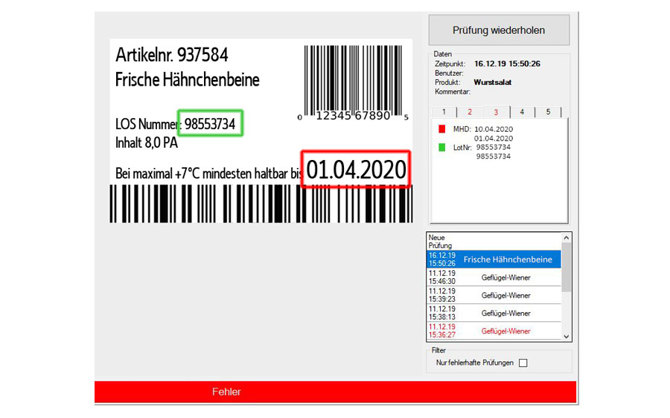

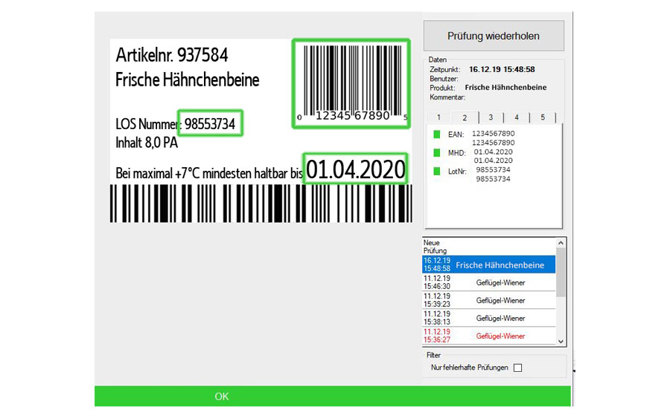

If production is now to start, all the required labels or foils of the product are placed on a test sheet for checking, which is then compared with the stored sample sheet from the database. If the system determines that all data is correct, production can start. If there is a discrepancy between label data and the data stored in the system, an error is reported, which can then be corrected before production begins.

In the inspection process, all types of labels, including outer packaging labels, are recognized and all identification numbers, codes, lot numbers and best-before dates are compared with the stored data set.

Industry-compatible complete solution from a single source

Verify codes, fonts and layouts – avoid errors and costs

Together with the expert for image processing and automation Strelen Control Systems GmbH we offer a complete total solution for measuring code verification according to ISO standards and layout control – the REA LabelTower.

The layout check by Strelen Control includes a plain text check, a check of graphic elements as well as variable data. Code verification by the REA VeriCube verifies code properties, contrasts and print precision.

The REA VeriCube transfers the captured image with the verification result to the Strelen software. There, a check is made for the correctness of the plain text or the entire label layout. The final verification result consists of the measurement-based code verification according to ISO/IEC standards and the layout check based on the label taught in before the start of production. Only when codes, fonts and layouts have passed the inspection is production released – no errors, no costs!

Advantages of automatic verification by Strelen and REA

Flexible, reliable detection and easy operation

- Font, layout and code verification with calibrated measuring device in one solution

- Inspection of variable label data for presence, correctness, readability and completeness

- Avoidance and prevention of misproductions

- Control and increase of data and code quality

- Use independent of industry

- Central recording and evaluation incl. Protocol

- User-friendly plug and play technology

- No cost-intensive inline verification necessary

- Code and character verification with CMOS camera system

- Exchangeable optics modules for optimum adaptation to different code sizes, label sizes, folding boxes, etc.

- Optimization of code print quality with highest first-pass reading rates

- Verification according to ISO/IEC 15415, the verification standard for printed matrix code

- Barcode verification according to ISO/IEC 15416 or ANSI X3.182

- ISO/IEC 15418 / ANS MH10.8.2 data structure analysis

- Special code selection for the requirements of serialized codes in the pharmaceutical industry