Welding with digital printing technology

Today, the high-precision laser welding process is increasingly used as an alternative to ultrasonic and high-frequency welding of plastics.

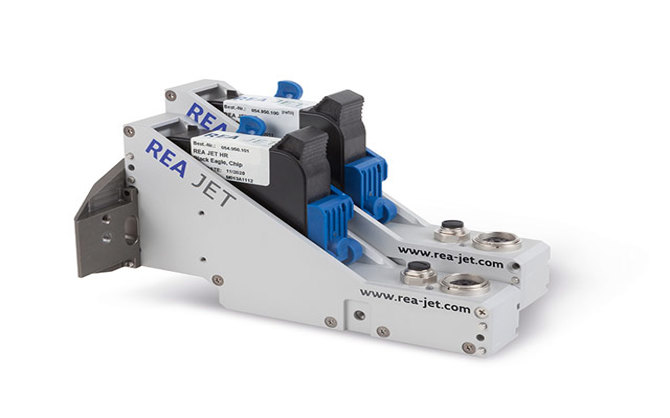

A prerequisite is the reliable and economical application of a complex additive. In the past, there was no industrial solution for this. Together with partners, REA JET has developed a highly interesting digital printing process using REA JET Clearweld Primer for automation.

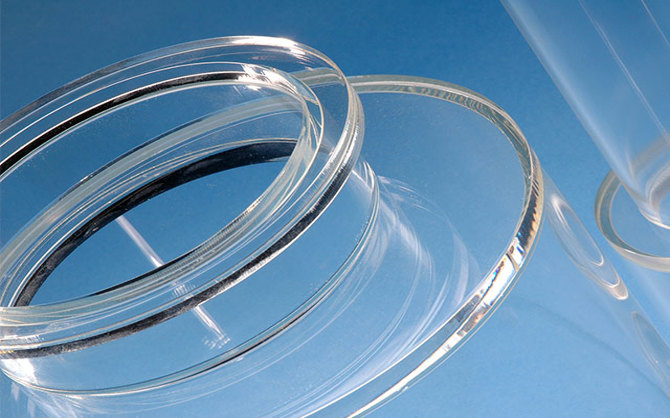

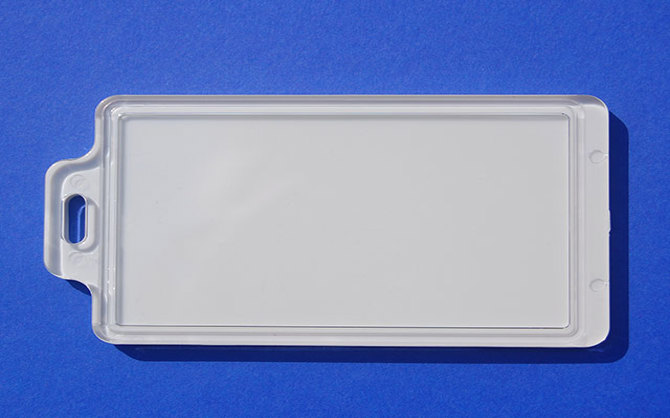

Classically transparent plastics, such as PE, PP, PC, PS, SAN have naturally only a limited laser absorption capacity, making plastic welding impossible or very difficult. With the REA JET solution, transparent and laser-transparent plastic materials can be prepared with the REA JET Clearweld Primer, which has a high specific laser energy, so that they can be welded with lasers. Injection-molded plastic parts as well as non-woven fabrics can also be welded with this solution.

Process Steps:

It works in these three steps…

- Coating Process

- Pre-assembly Process

- Welding Process

- REA JET´s field of competence

- Using REA JET HR printing technology transparent plastic parts will be economical and precise digital printed with REA JET Clearweld Primer

- The REA JET DOD 2.0 system issuitable for large areas

- The primer absorbs highly effectively specific laser energy

- Automated digital printing of primer for reproducible, cheaper and better welding results

- The REA JET Clearweld Primer dries within a very short time on the surface of the plastic part

- Positioning or pre-assembly of a second non-coated plastic part of the same material on the already coated plastic part in preparation for the welding process.

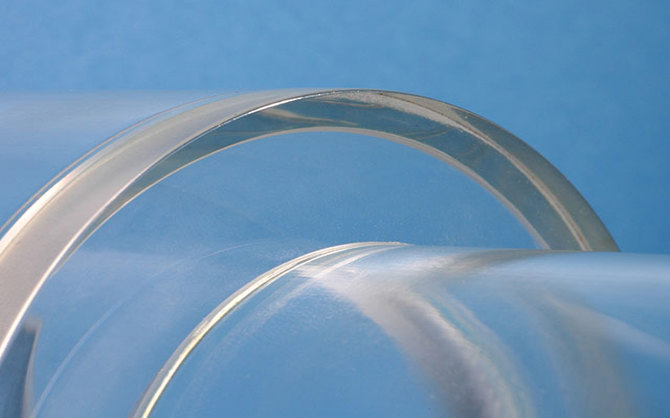

- While both parts are pressed against each other, specific laser energy is directed into the interfaces between the parts.

- The laser beam passes through the upper part and the laser energy is absorbed in the welding area.

- This generates heat that melts the plastic and welds the parts together.

- After plasticizing, the two parts are permanently joined together.